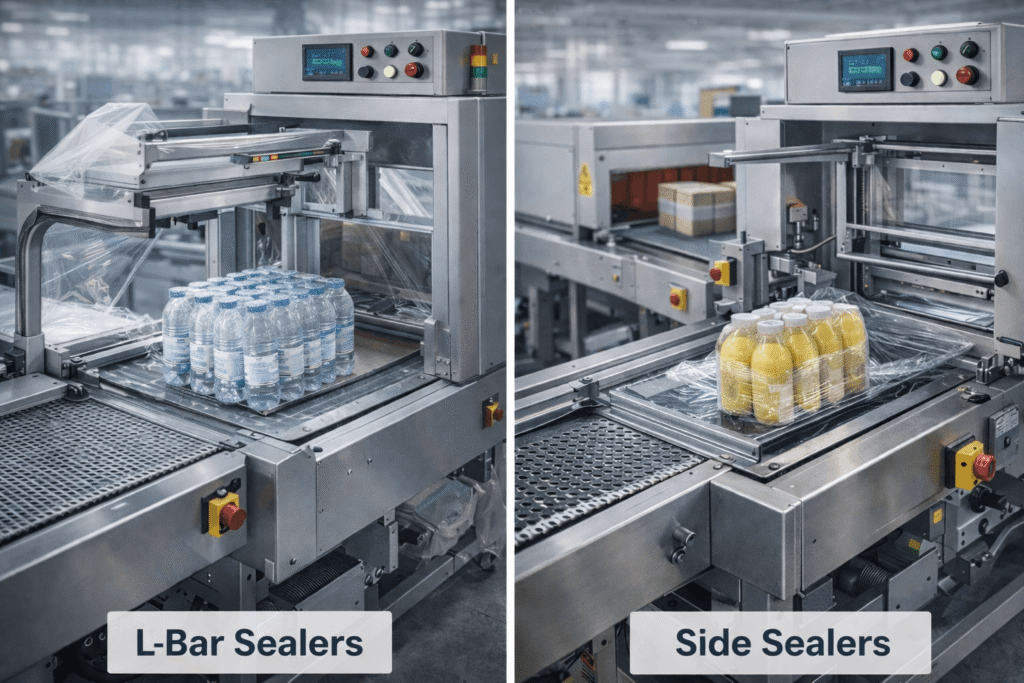

Choosing the right shrink wrap machines for your production line can significantly impact efficiency, cost savings, and product presentation. Two popular options dominate the packaging industry: L-bar sealers and side sealers. Both automated shrink wrap machine types offer distinct advantages, but understanding their differences is crucial for making an informed investment decision.

What Are L-Bar Sealers and How Do They Work?

L-bar sealers create a seal in an L-shaped pattern around your product. The machine forms two perpendicular seals simultaneously, one along the side and one along the bottom. This shrink packaging machine design works by positioning the product on a film, then lowering a heated sealing bar to create the enclosed package.

These systems excel at wrapping uniform products like books, DVDs, software boxes, and retail items. The sealing process is straightforward and requires minimal operator training. Most L-bar configurations operate at speeds suitable for low to medium-volume operations, typically handling 15 to 30 packages per minute.

The simplicity of L-bar sealers makes them cost-effective entry points for businesses beginning to automate their packaging processes. However, their speed limitations may not satisfy high-volume production requirements that demand greater throughput.

How Do Side Sealers Differ in Functionality?

Side sealers represent a more advanced auto wrapping machine technology designed for higher productivity. These systems seal products along their sides as they move continuously or intermittently through the machine. The sealing mechanism travels with the product, creating a consistent seal regardless of product length.

We offer both intermittent and continuous motion side sealers. Intermittent models stop briefly to seal each package, while continuous systems maintain constant motion for maximum efficiency. Continuous motion side sealers can process over 100 products per minute, making them ideal for high-volume operations.

Side sealers accommodate varying product dimensions without manual adjustments. This flexibility proves invaluable for manufacturers handling multiple SKUs. The systems work with products of different lengths, heights, and widths, adapting automatically to dimensional changes.

Which Industries Benefit Most from Each System?

L-Bar Sealers Best Serve:

- Retail packaging operations with uniform product sizes

- Small to medium businesses with moderate production volumes

- Companies packaging books, media, and consumer goods

- Operations prioritizing simplicity and ease of use

Side Sealers Excel in:

- High-volume manufacturing environments

- Food and bakery operations require consistent packaging

- Contract packagers handling diverse product portfolios

- Pharmaceutical and cosmetic companies need precision wrapping

The automatic wrapping machine specializes in matching businesses with the optimal system for their specific needs. Understanding your production volume, product variety, and growth projections helps determine which technology delivers the best return on investment.

What Are the Key Performance Differences?

| Feature | L-Bar Sealers | Side Sealers |

| Speed | 15-30 packages/minute | 100+ packages/minute |

| Product Variety | Limited to uniform sizes | Handles variable dimensions |

| Operator Skill | Minimal training required | Moderate technical knowledge |

| Initial Investment | Lower cost entry point | Higher upfront investment |

| Film Efficiency | Standard consumption | 10-15% material savings |

| Uptime | Good reliability | 98.5%+ operational uptime |

| Changeover Time | Quick for similar products | Fast film and dimension changes |

| Space Requirements | Compact footprint | Larger production area needed |

How Does Film Compatibility Impact Your Choice?

Film versatility plays a critical role in packaging operations. L-bar sealers typically work best with polyolefin shrink film, which provides excellent clarity and strength for retail applications. These machines handle standard gauge films effectively but may struggle with heavier materials.

Side sealers run all films equally well. Whether you need polyolefin for retail display, polyethylene for industrial protection, or biodegradable options for sustainability goals, these systems adapt seamlessly. This flexibility eliminates the need for multiple machines when working with different film types.

The servo motion control technology side sealers optimizes film tension and application. This precision reduces film waste by 10 to 15 percent compared to conventional systems. Over time, these material savings offset the higher initial equipment investment.

What Maintenance and Operating Costs Should You Expect?

L-bar sealers offer straightforward maintenance routines. Operators replace heating elements and Teflon tape periodically, tasks that require minimal technical expertise. The mechanical simplicity translates to lower service costs and less production downtime.

Side sealers incorporate more sophisticated components but deliver superior reliability. Our systems achieve 98.5 percent uptime even in multi-shift operations. The German-engineered machines eliminate compressed air requirements, reducing energy consumption and maintenance complexity. Servo technology regenerates energy during deceleration, further lowering operational expenses.

Can Your System Grow with Your Business?

Scalability considerations often determine long-term equipment satisfaction. L-bar sealers work well for stable production volumes but offer limited expansion capabilities. If your business experiences growth, you may need to purchase additional units or upgrade to higher-capacity systems.

Side sealers provide built-in scalability through adjustable speed settings and product handling flexibility. As production demands increase, the same machine accommodates higher throughput without replacement. This adaptability protects your equipment investment as your business evolves.

Our engineering systems that integrate smoothly into existing production lines. Our automatic wrapping machines require no field programming, making installation and setup efficient. The modular design allows for future additions like conveyors or heat shrink tunnels.

What Quality Standards Matter for Your Application?

Quality expectations vary across industries. Retail packaging demands pristine presentation with tight, wrinkle-free film application. Consumer products benefit from the clean seals that L-bar systems provide for individual items displayed on store shelves.

Industrial and pharmaceutical applications require consistent, tamper-evident packaging. Side sealers excel at delivering uniform results package after package. The precise temperature control and seal pressure produce professional-grade packaging that meets stringent quality standards.

ISO 9001 certification ensures the manufacturing processes maintain the highest quality benchmarks. Every machine undergoes rigorous testing before shipment. This commitment to excellence minimizes defects and maximizes production efficiency from day one.

Making the Right Investment Decision

Your choice between L-bar and side sealer shrink wrap machines depends on several factors. Evaluate your current production volume and anticipated growth trajectory. Consider product variety and dimensional requirements. Calculate the total cost of ownership including energy, materials, and maintenance.

For operations prioritizing simplicity and lower initial investment, L-bar sealers deliver reliable performance. Businesses requiring high-speed automation, product flexibility, and maximum efficiency gain competitive advantages through side sealer technology.

Contact us today for expert consultation. Our team analyzes your specific requirements and recommends the optimal shrink packaging solution. Experience the difference that German engineering and North American support deliver to manufacturers across food, pharmaceutical, cosmetic, and industrial sectors. Request a quote or schedule an on-site demonstration.