In the food and beverage industry, safety, purity, and compliance are non-negotiable. Every component that comes in contact with consumable products must meet strict regulatory standards—not just during production, but throughout the storage process. That’s why engineered food-grade liquid storage tanks play a vital role in maintaining product integrity from ingredient staging to final delivery.

Leading manufacturers provides food and beverage tank systems that meet FDA, NSF, and sanitary design guidelines, offering long-term durability and consistent compliance for high-throughput facilities.

Food & Beverage Industry Regulations Impacting Storage Equipment

Storage tanks used in food processing must comply with national safety frameworks, including:

- FDA 21 CFR Part 177 – Governs materials approved for food contact

- NSF/ANSI 61 and 372 – Regulate potable water system components

- 3-A Sanitary Standards – For dairy and CIP (Clean-in-Place) applications

- HACCP and GMP protocols – Enforced during food safety audits

Facilities may also face inspection from USDA, CFIA (in Canada), or third-party certifiers. Using tanks that already meet these requirements streamlines audit preparation and reduces the risk of contamination-related recalls.

Design Standards: Smooth Finishes, Anti-Leach Materials, and CIP Systems

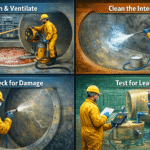

Sanitary tank design starts at the surface. Tanks that store edible liquids must be easy to clean, chemically inert, and free of imperfections that could trap microbes or residues. Required design features include:

- Polished or smooth internal surfaces – Reduce bacterial adhesion and support hygienic cleaning

- Anti-leach construction – Prevents chemicals or additives from migrating into the product

- Sloped or dish bottoms – Allow for complete drainage of product and cleaning solutions

- Clean-in-Place (CIP) compatibility – With spray balls or rotary heads for automated sanitization

- Ventilation ports and overflow control – Prevent unwanted exposure to air, dust, or condensation

Engineered food-grade storage tanks also include access ports for visual inspection and are built to withstand repeated cleaning without degrading the tank structure.

Choosing Tank Materials for Acidic, Sugary, or Dairy Liquids

Not all liquids pose the same storage challenges. Materials must be selected based on the properties of the stored product.

- Acidic liquids (e.g., fruit juices, vinegars): Require non-reactive linings or resin systems to avoid corrosion or flavor alteration.

- Sugary syrups and sweeteners: Need tanks that support smooth transfer and resist crystallization or caramelization.

- Dairy products: Demand strict temperature control, high-polish finishes, and validated CIP protocols to prevent bacterial growth.

FRP (Fiberglass Reinforced Plastic) is a popular option due to its chemical resistance, durability, and customizable features. For specialty or high-purity applications, stainless steel may be specified.

Manufacturers offers resin formulations and internal finishes explicitly designed for food-contact applications—ensuring compatibility and compliance with regulatory standards.

Durability Under Frequent Washdowns and Temperature Swings

In food-grade applications, storage tanks are frequently sanitized with caustics, acids, and high-temperature water or steam. This constant exposure can degrade untreated metals, plastics, or improperly bonded fittings.

Food storage tanks designed for industrial use must resist:

- Thermal expansion and contraction from rapid temperature changes

- Surface cracking or warping from high-pressure washdowns

- Chemical breakdown from cleaning agents or product residues

- Joint failure at welded or gasketed connections

Engineered food-grade tanks use materials and bonding techniques that withstand both physical and chemical stress, reducing the need for frequent repairs or early replacement.

Critical QA Steps in Working with Certified Tank Manufacturers

Partnering with a qualified tank manufacturer is key to ensuring compliance and longevity. Essential quality assurance steps include:

- Material traceability documentation

- Weld inspection and surface roughness validation

- Hydrostatic and pressure testing

- Post-fabrication cleaning and passivation (for metal tanks)

- Sanitary fittings, ports, and manways are included in the design

Certified food-grade storage tanks are often delivered with comprehensive QA documentation to meet the requirements of inspectors, customers, and internal compliance officers.

Lifecycle Cost Considerations for High-Throughput Facilities

While lower-cost tanks may seem attractive, they often fail to meet long-term performance and compliance requirements. Key cost-saving benefits of well-designed food-grade liquid storage tanks include:

- Reduced cleaning time due to better drainage and surface finishes

- Fewer batch failures caused by contamination

- Lower replacement and repair costs

- Easier regulatory compliance, avoiding fines or shutdowns

- Compatibility with automation and monitoring systems

When evaluated over a 10- to 20-year lifecycle, a premium tank system pays for itself many times over through improved safety, reliability, and efficiency.